Laboratory glassware takes shape through a precise and structured process that involves raw material, heat, shaping, and stabilization. Four stages that find a concrete parallel in the four natural elements — earth, fire, air, and water — at the core of processing 3.3 borosilicate glass, the reference material in Steroglass scientific glassmaking.

Earth: the molecular foundation of precision

Glass is born from sand, but not in its raw state. At Steroglass we use only 3.3 borosilicate glass, the result of a complex industrial process in which silica and boron are fused to obtain a chemically resistant, transparent, and thermally stable material.

Supplied in the form of tubes and rods of various diameters and thicknesses, this glass represents the starting point for the production of laboratory glassware and scientific instruments.

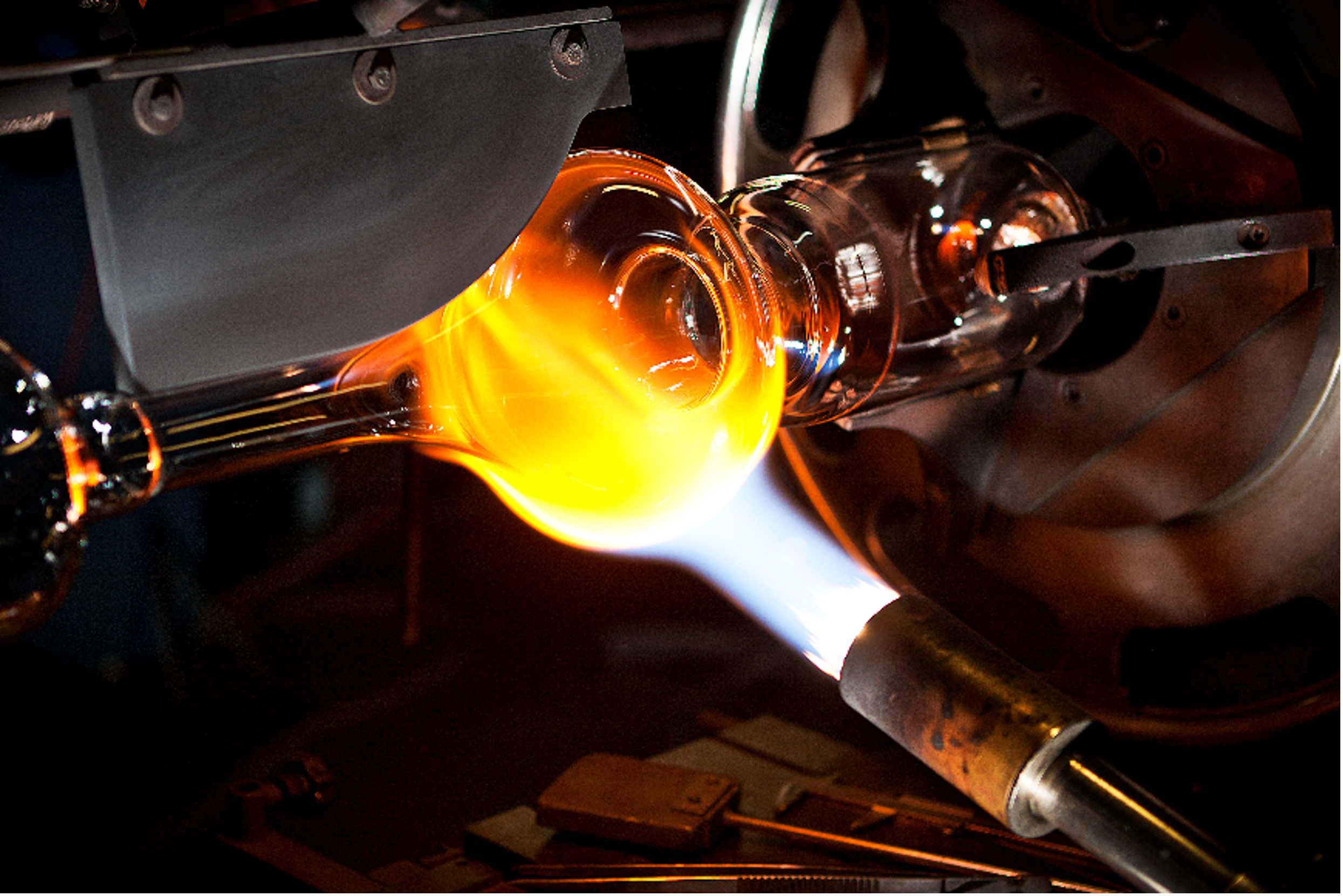

Fire: the threshold of transformation

Processing takes place at temperatures above 1000 °C, where glass becomes viscous, malleable, and ready to be shaped. The control of the flame — its intensity and direction — is essential to avoid thermal stress and maintain the structural integrity of the piece.

Each stage requires advanced expertise and a controlled technical environment, where fire is not just heat but a tool of precision.

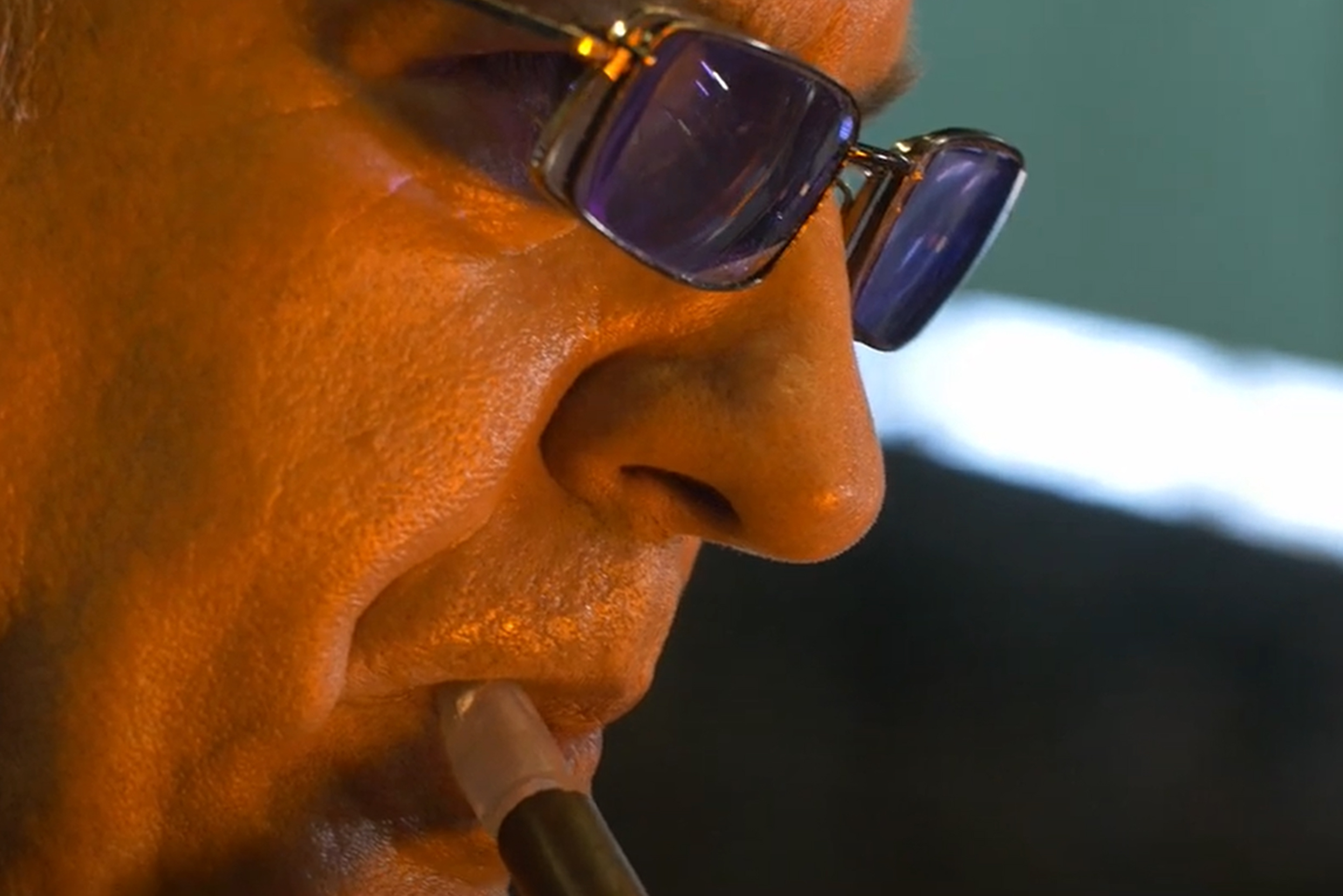

Air: the gesture that gives form

In blown glass, air is an active element. Not only as a gas used in the combustion system (propane, oxygen, compressed air), but also as calibrated pressure that the operator applies with skill to shape the molten glass.

The blow is not random: it is a refined technique that regulates volume, thickness, and geometry of the object, depending on its final use — whether it is a funnel, a distillation column, or a condenser.

Water: purity, transparency

Water comes into play as a metaphor for the transparency and chemical neutrality of borosilicate glass: inert, non-porous, and contaminant-free.

Like water, glass adapts without reacting, maintaining stability even when exposed to aggressive agents or high temperatures. This is an indispensable quality for laboratory glassware and instruments for chemistry, biotechnology, and pharmaceuticals.

Scientific glassblowing between tradition and innovation

Every component produced in the Steroglass glassblowing workshop is the result of a perfect integration of artisanal expertise and technical know-how. Manual craftsmanship, the use of certified 3.3 borosilicate glass, and the ability to produce custom or specific pieces make each item unique in terms of quality and reliability.

Whether standard laboratory glassware or specialized instruments for oenological or pharmaceutical applications, matter takes shape through a process in which natural elements and the rules of science operate in perfect synergy.