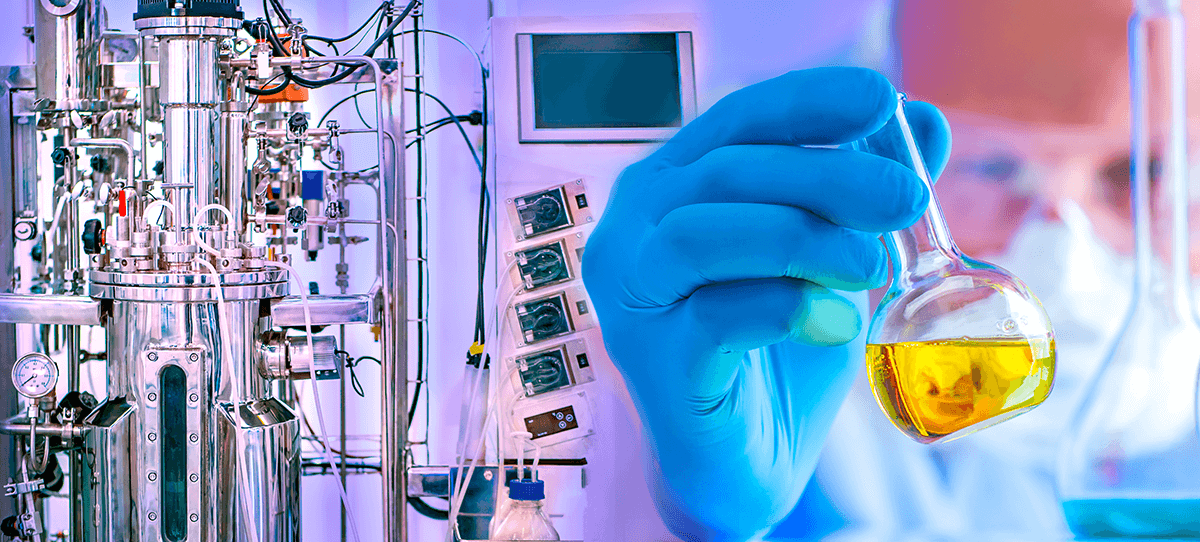

Enzymatic Analysis is an automated analytical technique for monitoring and controlling the fermentation of yeasts and bacteria.

This method is based on the use of highly specific enzymes that detect and quantify the presence of compounds of interest in various processes, such as glucose, lactate and ethanol.

Multiparameter enzyme analyzers are used to determine a wide range of analytes. They use a photometric measurement principle, i.e. the quantitative analysis is carried out by reading the variation in absorbance at different wavelengths, which is proportional to the concentration of the analyte being sought.

Hyperlab direct reading analyzers guarantee the lowest possible consumption of reagents, resulting in significant savings in operating costs. Complete automation means that the operator only has to insert the ready-to-use samples and reagents: the sampler arm collects the sample and the various reagents and dispenses them into a reaction cuvette, where they remain at a constant, controlled temperature for the time necessary for the complete development of the reaction and the reaching of the plateau. The analysis is monitored for the entire incubation time, and a graph displays the reaction kinetics.

Glucose monitoring during the stages of fermentation

During the fermentation processes of yeasts and bacteria, both for food applications and in the production of biotechnologies of various types and uses, it is necessary to quickly and accurately monitor several parameters, such as Ammoniacal and A-Amine Nitrogen, Ethanol, L-Lactic Acid, Acetic Acid, Acetaldehyde and, naturally, Glucose.

Glucose is the main source of energy for the microorganisms used in the fermentation process. During this process, microorganisms convert glucose into end products such as ethanol, lactic acid, acetic acid and other compounds, depending on the type of fermentation.

If glucose levels are not accurately controlled, a number of problems could arise which affect the yield of the fermentation process. For example, with low concentrations, the microorganisms may not have enough nourishment to carry out their vital functions, slowing down or even stopping fermentation. If instead glucose levels are too high, unwanted reactions may occur, with the producing of undesirable products as a result.

Glucose monitoring during fermentation thus makes it possible to optimize microorganism growth conditions, improve the yield of the fermentation process, produce high quality products and minimize waste. In addition, this monitoring is important for ensuring the safety of the fermentation process, as the levels of glucose and other compounds can affect the survival and growth of microorganisms and the presence of any contaminants.

Enzymatic analysis can be performed by using a Hyperlab multiparameter analyzer alongside the fermenter or bioreactor. Hyperlab’s automation is a guarantee of greater accuracy and precision in the results, with analysis costs seven times lower compared to manual methods.

In short, the Hyperlab analyzer allows you to:

- Reduce analysis times: results obtained in just a few seconds;

- Reduce the cost of each analysis: only a few μl of sample and reagent are needed;

- Improve analysis accuracy and reproducibility, avoiding any operator error.